Inverter HVAC Systems Explained: Performance, Efficiency, and Installation Best Practices for Contractors

As an HVAC contractor, you regularly file client complaints about skyrocketing utility bills and uneven comfort from traditional fixed-speed systems. Inverter HVAC systems address these issues head-on with variable-speed technology. This article outlines their key benefits, including significant energy savings and improved part-load efficiency compared to fixed-speed systems.

As inverter-driven systems become more common, contractors who understand how and why these systems operate differently are better positioned to size, install, and commission them correctly, thereby avoiding callbacks and performance complaints.

To compare inverter system options and verify efficiency ratings, contractors can use the GREE System Builder.

Introduction to Inverter HVAC Systems

For HVAC contractors, the shift from traditional single-stage systems to inverter-driven technology represents a fundamental change in how we approach climate control. You are likely to see increased demand for high-efficiency units, driven by rising energy costs and stricter regulations. Inverter systems are no longer a niche product; they are becoming the standard for residential and light commercial applications.

Understanding the technical advantages of these systems allows you to better serve your clients and reduce callbacks. Select GREE inverter-driven systems achieve very high SEER2 ratings, significantly exceeding current minimum efficiency requirements. This article breaks down the mechanics and benefits of inverter technology so you can confidently recommend and install the right equipment for the job.

What Are Inverter HVAC Systems?

At its core, an inverter HVAC system utilizes a Variable Frequency Drive (VFD) to control the speed of the compressor motor. Unlike standard rotary compressors that operate on a strictly binary basis, an inverter compressor can modulate its output. In HVAC applications, inverter control is integrated with system sensors and logic boards to manage compressor speed dynamically based on real-time load.

The process involves converting the incoming AC power supply into DC voltage and then modulating that DC power to create a variable frequency AC output. This allows the compressor to operate at varying speeds rather than just full capacity or zero. By adjusting the frequency of the electrical current, the system precisely dictates the rotational speed of the compressor, matching the refrigerant flow rate to the immediate heating or cooling load required by the conditioned space.

For model-specific inverter architecture and control details, reference GREE's system documentation before design or installation.

How Inverter HVAC Systems Work

The operation of an inverter system centers on load matching. When you turn on a traditional unit, it blasts at 100% capacity until the thermostat is satisfied, then shuts off completely. This results in significant temperature fluctuations and energy spikes.

In contrast, an inverter system analyzes the temperature differential between the setpoint and the ambient air.

- Startup: It ramps up quickly to reach the target temperature

- Modulation: Once close to the setpoint, the compressor slows down

- Maintenance: It runs continuously at a low speed to maintain the temperature within a fraction of a degree

This continuous operation eliminates the energy-intensive stop-start cycles that plague single-stage systems, reducing mechanical stress and electrical inrush current.

See real-world inverter operation and startup procedures in GREE's instructional videos.

Energy Efficiency and Lower Utility Bills

The primary selling point for most clients is the return on investment through energy savings. Because the compressor rarely runs at full load after the initial pulldown, the system consumes significantly less power during operation. Inverter compressors are most efficient at partial load conditions, which account for most of the run time.

Data indicates that GREE mini-split systems with inverter technology can deliver substantial energy savings over fixed-speed systems, particularly under part-load operating conditions. With high SEER2 ratings available in select inverter-driven models, these systems maximize every watt of electricity used. For your clients, this translates to drastically lower monthly utility bills, often offsetting the higher initial installation cost within a few years of operation.

To size and configure an efficient inverter system correctly, contractors can use the GREE System Builder. Homeowners should consult a qualified GREE contractor for application-specific savings.

Precise Temperature Control for Consistent Comfort

One of the most noticeable benefits for the end-user is the elimination of temperature swings. Traditional systems often allow the room temperature to drift 2 to 4 degrees from the setpoint before the thermostat triggers a cycle. This creates uncomfortable "hot and cold" spots throughout the day.

Inverter systems monitor the room conditions constantly. By making micro-adjustments to the compressor speed, they maintain the indoor temperature within a much tighter temperature band than traditional fixed-speed systems. This precision ensures that the client experiences consistent comfort without the blast of cold air followed by a period of stagnation. This level of control is particularly beneficial in multi-zone applications where load requirements vary room by room.

Quieter Operation Compared to Traditional Systems

Noise complaints are a common issue with traditional outdoor condensing units, especially in dense residential areas. The hard start of a single-stage compressor creates a noticeable surge in decibels, often followed by vibration. Inverter systems solve this through soft start technology and low-speed operation.

Because the compressor ramps up gradually and often runs at lower RPMs, the operational noise is significantly dampened. GREE inverter technology keeps indoor and outdoor components significantly quieter in operation than traditional fixed-speed systems, particularly at part load. This makes these systems ideal for installations near bedrooms, patios, or in strict HOA communities where noise pollution is regulated.

Extended Lifespan and Reduced Maintenance Costs

Frequent cycling is the enemy of mechanical longevity. The constant on/off cycling of a traditional compressor places immense stress on the motor windings, capacitors, and bearings due to high inrush currents during startup.

Inverter systems mitigate this wear and tear in several ways:

- Soft Starts: Gradual acceleration reduces electrical and mechanical shock

- Fewer Cycles: Continuous low-speed operation means fewer start-up events per day

- Reduced Friction: Lower average RPMs mean less friction and heat generation within the compressor

While the electronic components are more complex, the core mechanical components often last longer. Actual service life depends on proper installation, airflow, refrigerant charge verification, and adherence to manufacturer maintenance guidelines. This reliability reduces the frequency of emergency repair calls and extends the overall service life of the equipment for your client.

Superior Humidity Control for High-Humidity Climates

For contractors in humid regions, latent heat removal is just as critical as sensible cooling. Traditional systems are often short-cycle during mild weather, cooling the air quickly but shutting off before they can effectively remove moisture. This leads to a cold, clammy indoor environment.

Inverter systems excel here because of their long run times. By running continuously at a lower capacity, the evaporator coil stays cold for extended periods. This allows for sustained dehumidification, pulling more moisture out of the air without overcooling the space. This capability is essential for preventing mold growth and maintaining indoor air quality in high-humidity zones. Proper airflow setup and correct equipment sizing are critical to achieving these humidity control benefits.

Proper sizing and setup are critical; verify latent load handling using manufacturer documentation and installation guidance.

Faster Heating and Cooling Response

While efficiency is key, clients also want immediate comfort. Inverter systems feature "turbo" or high-frequency modes that allow the compressor to temporarily operate above nominal speed within manufacturer-defined limits to accelerate pull-down or warm-up.

When a user adjusts the thermostat significantly or turns the system on after a long period, the inverter drives the compressor to maximum speed immediately. This results in much faster pull-down or heat-up times compared to fixed-speed units. Once the setpoint is approached, the system seamlessly throttles back to an energy-saving maintenance speed. This ability to sprint when necessary and jog when possible gives your clients the best of both worlds.

Best Practices for Maximizing Inverter HVAC Benefits

To ensure these systems deliver on their promises, installation and application must be precise. Technology is forgiving of load variations, but not of poor installation practices.

Proper Sizing for Your Home

Even with variable speed technology, proper sizing is non-negotiable. An oversized inverter unit may not ramp down low enough to dehumidify effectively, which is problematic in humid climates. Conversely, an undersized unit will run at 100% capacity constantly, negating efficiency gains. Perform an accurate ACCA Manual J load calculation that accounts for the specific sensible and latent loads of the structure.

Professional Installation Essentials

Inverter systems rely on sophisticated electronics and sensors.

- Wiring: Use the correct stranded, shielded wire (as specified by the manufacturer for the specific model and application) to prevent communication errors between indoor and outdoor units

- Flaring: Precision flaring is critical to prevent refrigerant leaks, as these systems are sensitive to charge levels

- Vacuum: Evacuate the system to the micron level specified in the manufacturer's installation instructions

GREE Training and Instructional Videos provide step-by-step guidance for inverter system wiring, evacuation, and startup.

Ongoing Maintenance Tips

Educate your clients on their role in system health.

- Filter Cleaning: Clean filters monthly to maintain airflow across the sensors

- Coil Cleaning: Dirty coils disrupt the heat transfer calculations that the inverter logic relies on

- Clearance: Ensure the outdoor unit has proper clearance for airflow

Regular professional maintenance checks should focus on verifying error codes and checking thermistor accuracy.

Common Mistakes to Avoid with Inverter Systems

The most frequent issues with inverter installations stem from treating them like standard split systems.

- Ignoring Torque Specs: Overtightening flare nuts causes leaks; always use a torque wrench

- Cutting Control Wires: Never splice the communication wire between units. It creates signal interference

- Line Set Length: Exceeding the maximum line set length without adding the manufacturer-specified refrigerant trim charge will compromise performance. Always verify maximum line length, elevation limits, and any required additional charge in the manufacturer's documentation

- Mounting Location: Placing the indoor unit thermostat sensor near heat sources (like lamps or TVs) will confuse the inverter logic, causing erratic operation

Most inverter issues can be avoided by following model-specific installation limits and documentation from GREE.

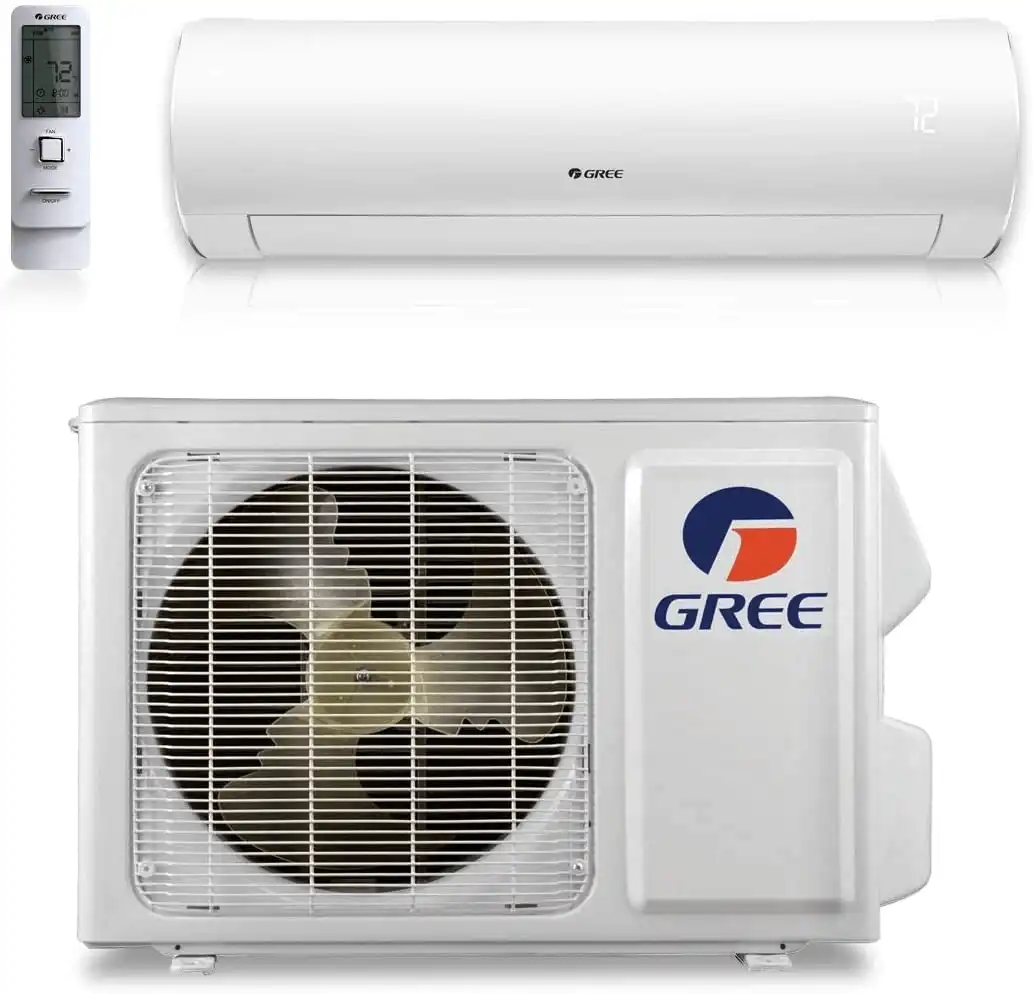

Why Choose GREE Comfort Inverter HVAC

GREE is a global manufacturer with a strong focus on inverter-driven HVAC technology. Systems such as GREE's inverter-driven multi-zone platforms are designed to operate across a wide range of outdoor temperatures, depending on the model.

GREE's proprietary G10 inverter technology provides wider frequency operation, reducing vibration and noise while maximizing efficiency. By choosing GREE, you provide your clients with equipment that is robust, technologically advanced, and backed by extensive support networks.

Conclusion

Inverter HVAC systems offer a superior solution for modern climate control, delivering unmatched efficiency, quiet operation, and precise comfort. As a contractor, mastering the installation and service of these systems positions you as a leader in the industry. The benefits, ranging from lower utility bills to better humidity control, make the conversation with homeowners straightforward and compelling.

HVAC Contractors: Get the Right Info, Tools, and Support

Use GREE's contractor resources to configure inverter systems, verify installation requirements, and support long-term service. Build approved configurations with the GREE System Builder, access current manuals through System Documentation, and reinforce best practices with GREE Training and Instructional Videos.

Homeowners: Work With a Qualified GREE HVAC Professional

Proper sizing, installation, and service are critical for inverter HVAC performance. Use the GREE Contractor Locator to find a trained HVAC professional in your area.

Frequently Asked Questions

What is the difference between inverter and non-inverter HVAC systems?

Inverter systems use a variable frequency drive to modulate compressor speed continuously, while non-inverter units cycle on/off at full capacity. This results in inverter systems providing better efficiency, quieter operation, and precise temperature control compared to fixed-speed compressors.

How long does an inverter HVAC system typically last?

Service life varies by installation quality, operating conditions, and maintenance practices; inverter systems benefit from reduced cycling when installed and maintained correctly. Regular filter cleaning and annual professional inspections extend this lifespan further.

Are inverter HVAC systems more expensive upfront?

Yes, inverter systems typically have higher upfront costs but can offset that investment over time through improved efficiency and reduced operating costs. Payback typically occurs within 3-5 years via lower utility bills.

Can inverter systems be used in very cold climates?

GREE inverter systems like the Multi+ Ultra operate reliably down to -31°F with 2-stage/3-cylinder compressors, maintaining heating capacity without auxiliary heat. Low ambient kits enhance performance in sub-zero conditions.

What maintenance is required for inverter HVAC systems?

Monthly filter cleaning, annual coil inspections, and verifying thermistor readings are essential. Verify system operation and charge according to the manufacturer's service procedures during professional maintenance.